Features

Electro-mechanical mobile column lifts.

Operating features

-

Electronic system ensuring synchronization of all columns

-

Master column: with all selection and controls.

-

Slave column: with lifting and lowering controls and emergency stop button.

-

Selection of several operating modes:

– simultaneous operation of all columns

– simultaneous operation of one or more pairs of columns

– single operation of each column.

Large and solid base for maximum stability under load.

Lifting spindles in rolled steel with bronze main and safety nuts. Thermal protection against overload of motors.

MOBI 30 – 40 – 55

Screws are automatically lubricated by felt pads located in the oil reservoir over the lifting nuts, assuring permanent lubrication during movement.

A series of runners (10 per carriage), manufactured in Ertalon with low friction coefficient and excellent resistance to wear, guarantee safe lifting.

MOBI 70 – 85

Columns in boxed sheet steel with rollers sliding profiles in high resistance steel. Steel rollers for carriage movement fitted on self-lubricating bearings requiring no maintenance. Direct drive to the spindle by means of a self-braking motor-gear unit.

MOBI 70E – 85E

Outdoor version.

|

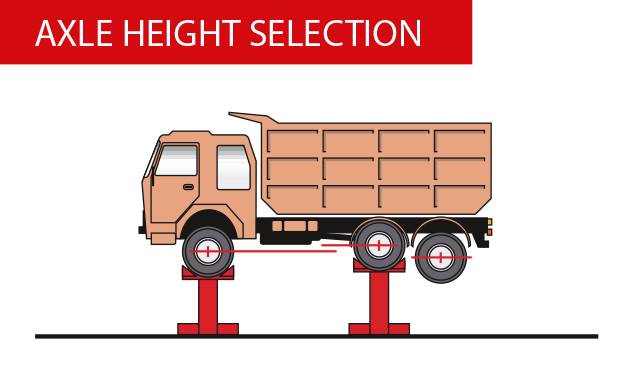

Possibility of setting a different height between pairs of columns while retaining the level synchronization. |

|

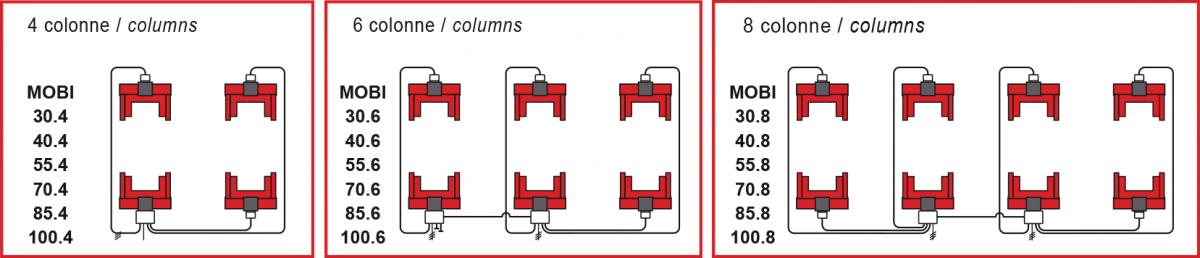

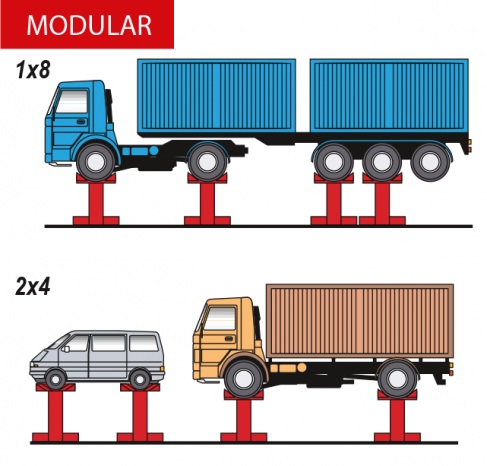

Modular electrical systems (e.g. passing 4 to 6 to 8 columns, or creating two sets of 4 columns by splitting a set of 8). |

|

MOBI 30 – 40 – 55 – 70 – 85Self-supporting transportation steel wheels. |

|

MOBI 30, MOBI 40 → VAR210-220/F

|

MOBI 30.4N (4 x 3000 kg)

MOBI 40.4N (4 x 4000 kg)

MOBI 55.4N (4 x 5500 kg)

-

Simultaneous operation of 4 columns.

-

Not extendible to 6 or 8 columns

-

Master column with controls.

-

Slave column with emergency control only.

|

U TYPE: UNIVERSAL CARRIAGEUniversal carriage offers the possibility of using special pick-up adapters for lifting speciaI vehicles. |

MOBI 55.5NF

For fork lifts.